For any plant option created with PDE, the user can also obtain a fuel-demand model characterizing performance across a range of ambient and load conditions. The senior staff have all been carefully selected and trained by the founder. Modelling GTs in Thermoflow Programs. When the optional through-flow node is connected, this icon behaves like a flow dictator with user-selectable priority. With close to ten thousand individual programs sold, and about three thousand users in 80 countries, Thermoflow today has the largest share of the world market. This gas stream dries and transports the fuel to a beater mill which pulverizes it and drives it to the burners.

| Uploader: | Nadal |

| Date Added: | 17 December 2006 |

| File Size: | 54.77 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 4950 |

| Price: | Free* [*Free Regsitration Required] |

We think you have liked this presentation.

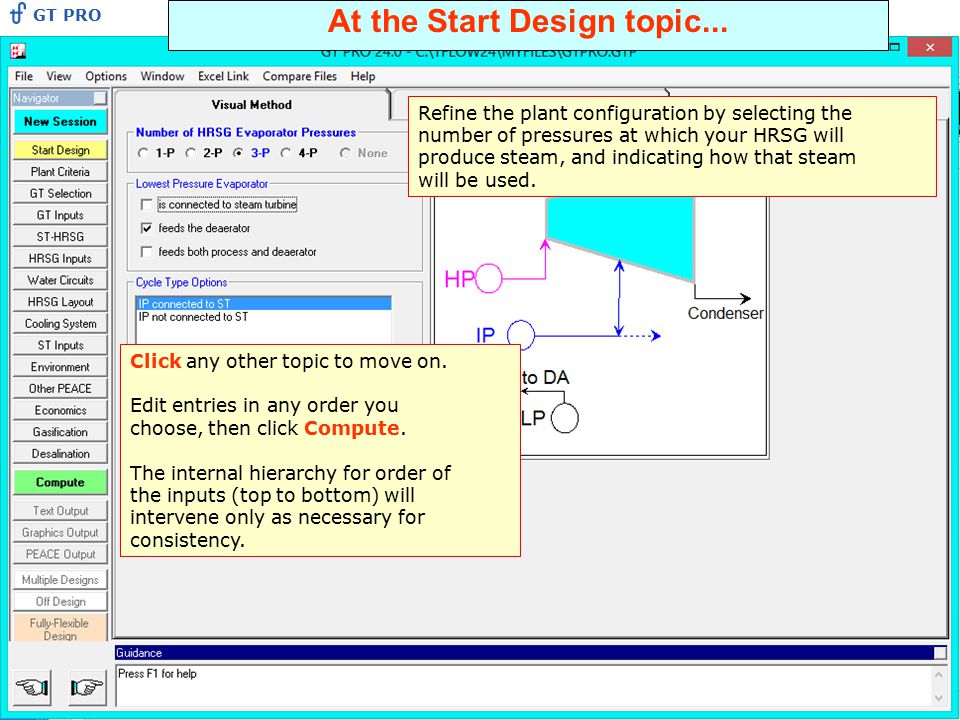

WHAT IS GT PRO? Thermoflow Inc.

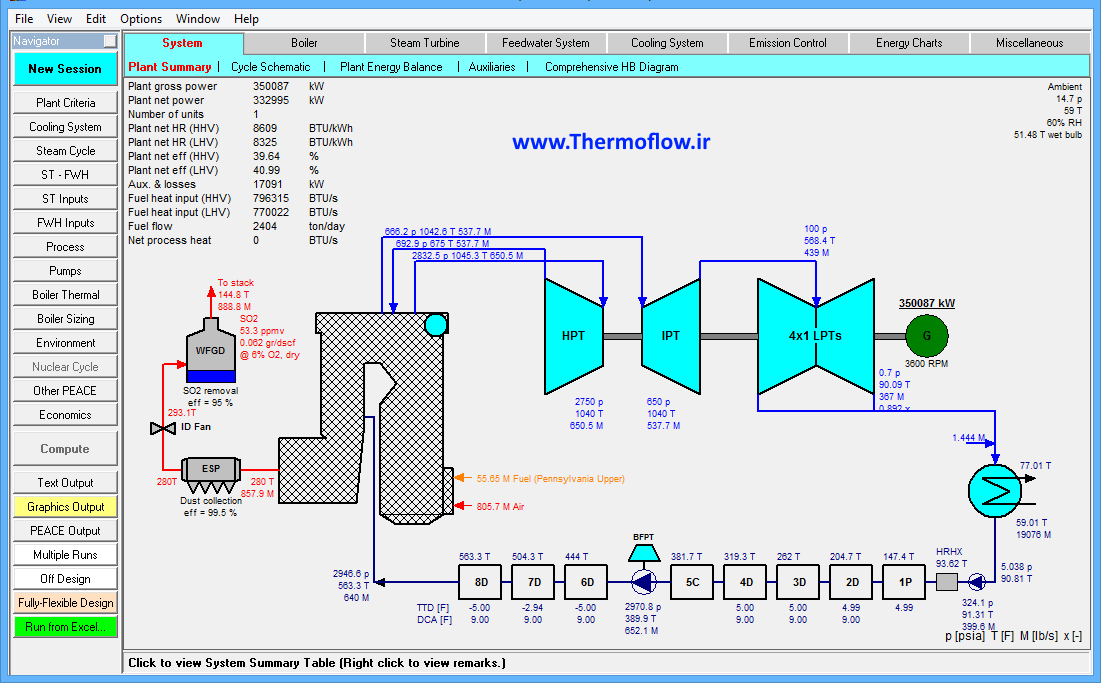

However, re-running old files using this new logic will yield changes in computed boiler size, weight, and cost. Other details of the turbine can be edited in the underlying tabs. Select a gas turbine from over available engines, including all major vendors.

Labor rates, commodity costs, and prices for 'Other Equipment' were revised to reflect inflation. Revise inlet and exhaust draft losses. Registration Forgot your password? Process streams supplied solely ht extraction from the steam turbine are defined here.

Select to inject water or steam.

Thermoflow

An SCR for conventional boilers was included and is located on this tab. Indeed, many have ordered new Thermoflow products sight unseen, without asking for demos or trials, based on the confidence developed over years of customer satisfaction with other Thermoflow products.

Share buttons are a little bit lower. A tg detailed combustion air heating and delivery model was introduced along with a model of an air-swept coal pulverizer.

GT PRO / GT MASTER / PDE

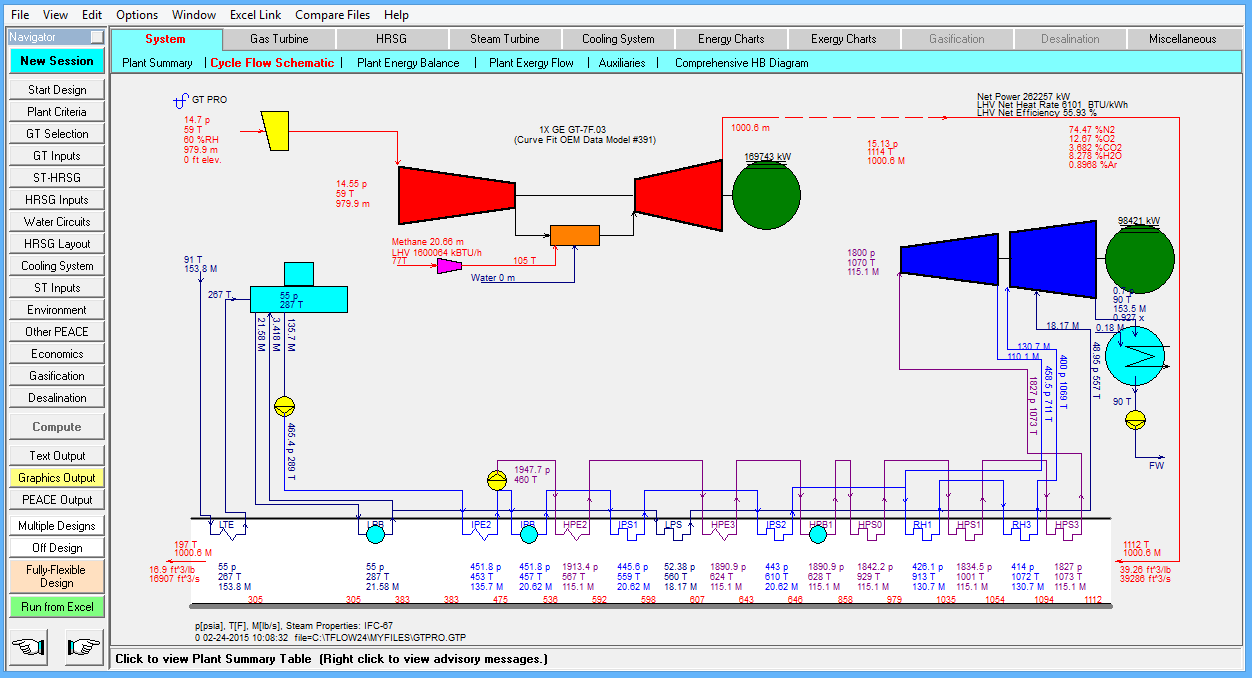

A walkthrough of the process of building a model, from connecting components to make a cycle and specifying inputs for the model. Gas turbine prices for particular engines were revised based on informal feedback from some OEMs. Note also the many other graphic displays to be selected from the tabs above.

Whereas gross errors are obvious, subtle modeling inaccuracies that produce no violations of heat and mass balances generally go unnoticed. Feedback Privacy Policy Feedback. Note the two columns: PDE takes away much of GT PRO's flexibility and replaces it by a high degree of automated, expert logic to identify suitable schemes, configuration details, and design parameters. Click on Cash Flow to see a pro forma financial projection.

Thermoflow Tutorials & Videos

Upcoming Features in Version This is especially true in predictive off-design simulation of components and systems, where unsatisfactory modeling techniques can remain undetected by the typical user for years.

Advanced engineering talent is not just used to derive the models thernoflow direct program development, but rhermoflow actually write the programs, and then only after an extensive period of training and observation at Thermoflow.

Clicking anywhere on the diagram causes the data to be displayed in tabular form.

The last four buttons let you: It lets you adjust performance, over a range of ambients and engine load conditions, for any GT in the extensive library, to match updated vendor data. Tuning features have been included for major equipment to permit entering vendor guarantee points, and instruct GT MASTER to derive correction factors to superpose on its underlying physical models to match these guarantee points, then logically interpolate between them at other conditions.

This has minimized errors or oversights, all too common in large engineering models, and ensured that all modeling approximations are fully analyzed and understood before being carefully incorporated into the programs.

It now includes over panels from ten manufacturers. At off-design, controls are in place to achieve desired fuel temperature delivered to the burners, and to control the air flow to the pulverizer in accordance with fuel transport requirements. Adding A Heat Recovery Boiler. This allows the user to create and compare many plant options, and variations within each, to find the most suitable theemoflow, both technically and economically.

Tabs are used as necessary to subdivide topics; green tabs include PEACE inputs Every entry box has been initialized with a reasonable value. Syngas enthalpy functions were improved in the temperature range — F, — C. A walkthrough of the Thermof,ow PRO program, both input and output screens, complete with voice-over narration and description of the inputs.

Комментариев нет:

Отправить комментарий